Introduction

In the hustle and bustle of industrial operations, finding ways to be efficient and accessible is more important than ever. Think about it: how often do you find yourself scrambling for tools or supplies? That’s where industrial vending solutions come in. They’re like a breath of fresh air, offering automated access to what you need while making inventory management a breeze.

But here’s the thing: implementing these systems isn’t always smooth sailing. There are challenges and considerations that can really make or break your investment. So, what can you do to ensure these systems fit right into your existing workflows? And how can they actually help boost productivity and save you some cash?

Let’s break it down. First off, it’s all about understanding the key practices that lead to successful implementation. You want to make sure these solutions not only integrate seamlessly but also deliver real value. So, what’s the first step? Start by assessing your current processes and identifying where these vending solutions can make the biggest impact.

By taking a closer look at your operations, you can pinpoint the areas that need improvement. This way, you’re not just throwing a new system into the mix; you’re making a strategic move that can really pay off. So, are you ready to dive in and explore how industrial vending can transform your operations?

Understand Industrial Vending Machines and Their Functionality

Have you ever found yourself scrambling to find the right tools or supplies in a busy industrial setting? It’s a common headache, but there’s a solution that can make life a lot easier: industrial vending solutions. These automated systems are designed to dispense everything from tools to personal protective equipment (PPE) in various industrial environments. They come in different styles, like coil machines and locker systems, tailored to meet specific needs.

One of the standout features of these machines is their stock management capabilities, which get a serious boost from RFID technology. This nifty tech allows for automatic tracking of items as they’re dispensed, helping you keep tabs on stock levels and reducing the risk of running low on essential supplies. For example, in the aerospace industry, RFID-enabled dispensers provide secure storage and controlled access to certified tools, enhancing quality assurance and minimizing the loss of expensive components.

But that’s not all — RFID technology also helps with real-time data collection on stock levels and usage patterns. This means smoother operations and better accountability in managing your inventory. As the market for industrial automated systems is set to grow significantly, with a projected CAGR of 10.1% from 2024 to 2029, driven by tech advancements and the need for efficient supply management, the implementation of industrial vending solutions and RFID technology is becoming essential for businesses looking to boost their operational efficiency.

According to Fastenal, "The market for industrial vending solutions is experiencing significant expansion, driven by a confluence of factors that are reshaping how businesses manage their operational supplies, tools, and personal protective equipment (PPE)." So, if you want to stay ahead of the curve, consider integrating these advanced systems into your operations. They can help ensure your stock management processes are not just effective but also reliable.

Leverage the Benefits of Industrial Vending Solutions for Enhanced Efficiency

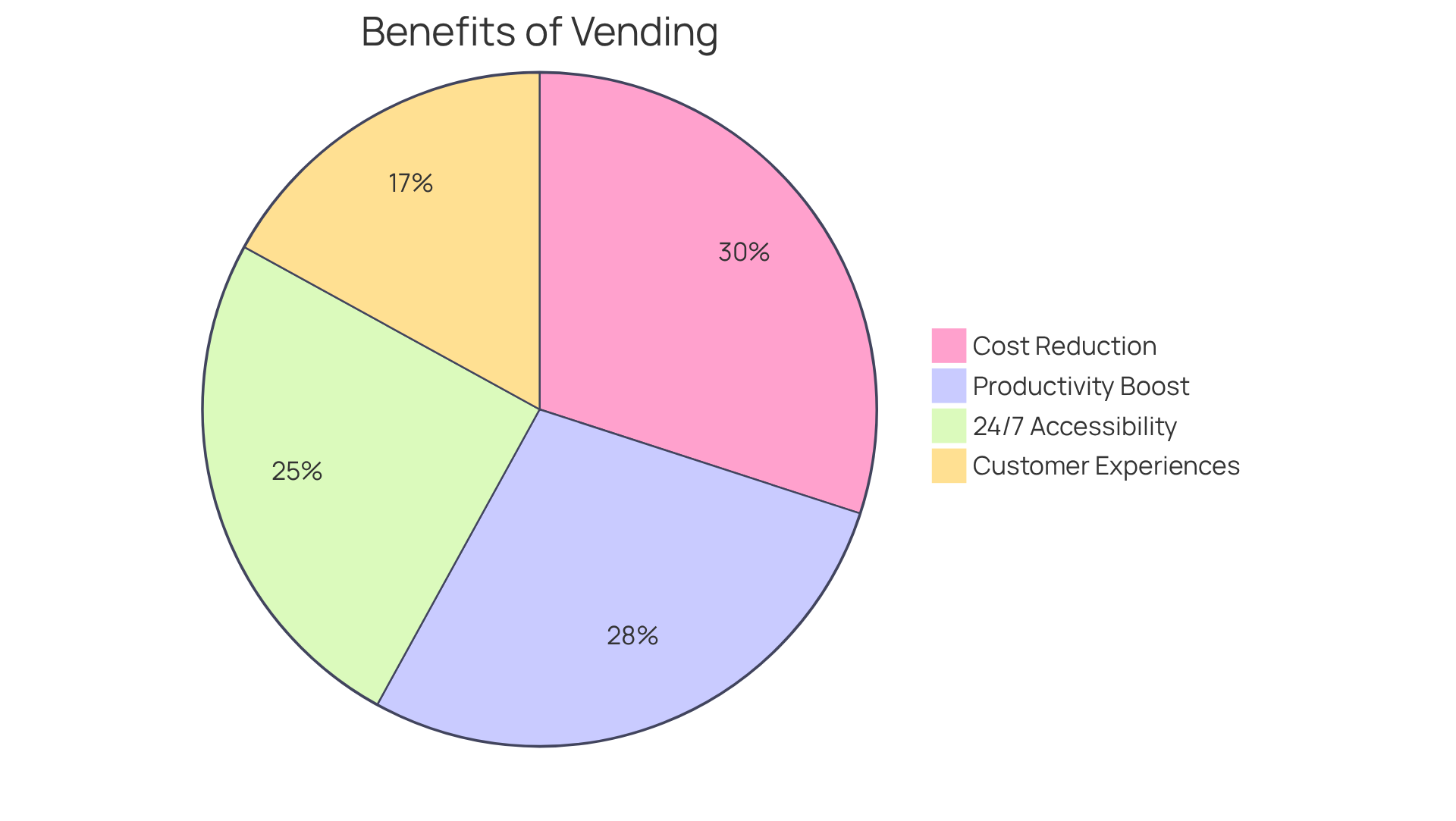

You know how frustrating it can be when you can’t find the tools you need right when you need them? Implementing industrial vending solutions can really change the game. These devices can help you cut inventory costs by up to 30% by reducing excess stock and waste. That’s a big deal!

But it doesn’t stop there. They also boost employee productivity by making sure everyone has immediate access to essential tools and supplies. Less downtime means more work gets done. One happy customer put it perfectly: "Vending Village has seriously transformed our business. We're way more productive and seeing great results."

Another user from Healthy Snaxs Vending shared their experience: "I bought a location, but it wasn't a fit. I got a full refund - no questions asked. Just as advertised!" It’s great to hear stories like these, right?

Take a look at this: a case study from a manufacturing plant showed a whopping 28% rise in productivity after they set up automated dispensers. Workers didn’t have to waste time looking for tools or waiting for materials anymore. Plus, these machines work around the clock, giving employees access to what they need at any time. That’s a huge advantage in busy environments.

By streamlining inventory management and enhancing accessibility, industrial vending solutions can truly position your business for success. So, why not consider making the switch? It could be just what you need to take things to the next level!

Implement Industrial Vending Solutions: Best Practices for Success

When it comes to implementing industrial vending solutions, there are a few best practices that can really make a difference. Let’s dive into them.

-

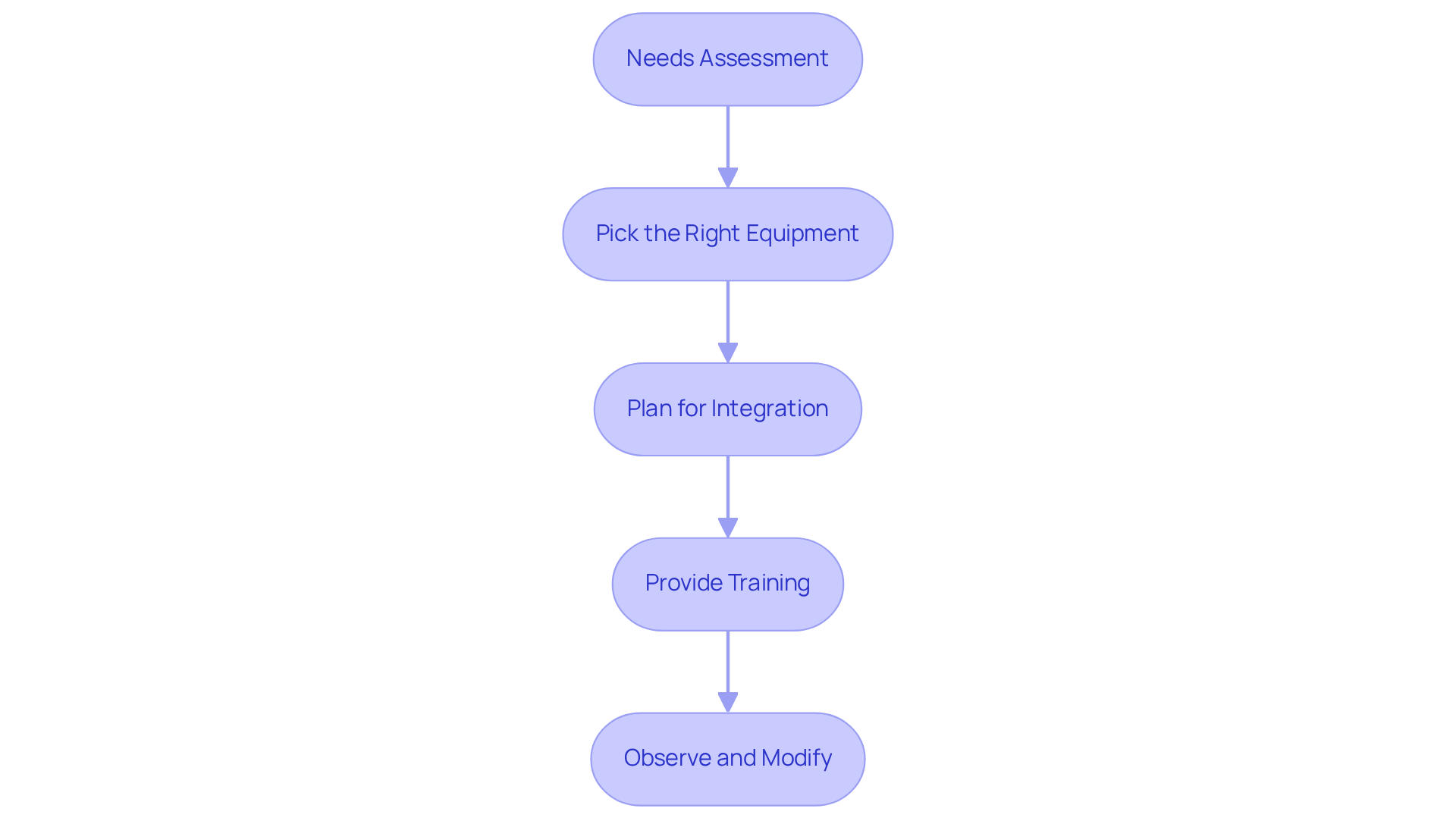

Start with a Needs Assessment: First things first, take a good look at what your workforce actually needs. Check out usage trends and identify which products get restocked the most. This step is super important because a solid needs assessment can really boost how effective your solution is. If you skip this, you might end up with the wrong dispensers, and that can slow things down.

-

Pick the Right Equipment: Next up, choosing the right equipment is key for everything to run smoothly. For instance, if you’re dealing with small parts, coil dispensers are a great fit. But for larger items, you might want to consider a cabinet or locker system. Matching the equipment to what you’re dispensing can really improve accessibility and keep users happy.

-

Plan for Integration: Now, let’s talk about integration. Make sure your vending machines can easily connect with your current stock management systems. This way, you can track and report in real-time, which is crucial for keeping inventory levels just right. Plus, organizations that get this right can cut equipment procurement costs by up to 22%. That’s some serious savings!

-

Provide Training: Don’t forget about training! It’s essential for making sure everyone knows how to use the equipment effectively. Training should cover how to access items, report issues, and make the most of the data the machines provide. Companies that invest in training see higher adoption rates and fewer mistakes. In fact, 94% of employees would stick around longer if their employer invests in their growth. That’s a win-win!

-

Observe and Modify: Finally, after you’ve implemented everything, keep an eye on how the dispensers are performing. Use the data you gather to make smart decisions about inventory levels, where to place equipment, and any upgrades you might need. Regular check-ins can lead to better efficiency and cost savings as you adapt to changing needs. Did you know the automated retail machine industry boasts a success rate over 80%? There’s even a chance for a 100% return on investment within 12 to 18 months. That’s why starting with a solid needs assessment is so crucial.

By implementing these best practices, your organization can achieve success with industrial vending solutions, thereby enhancing efficiency and productivity.

Address Challenges and Considerations in Industrial Vending Implementation

Implementing industrial vending solutions can yield significant benefits, but let’s be honest — there are a few challenges you’ll need to navigate to maximize their effectiveness.

-

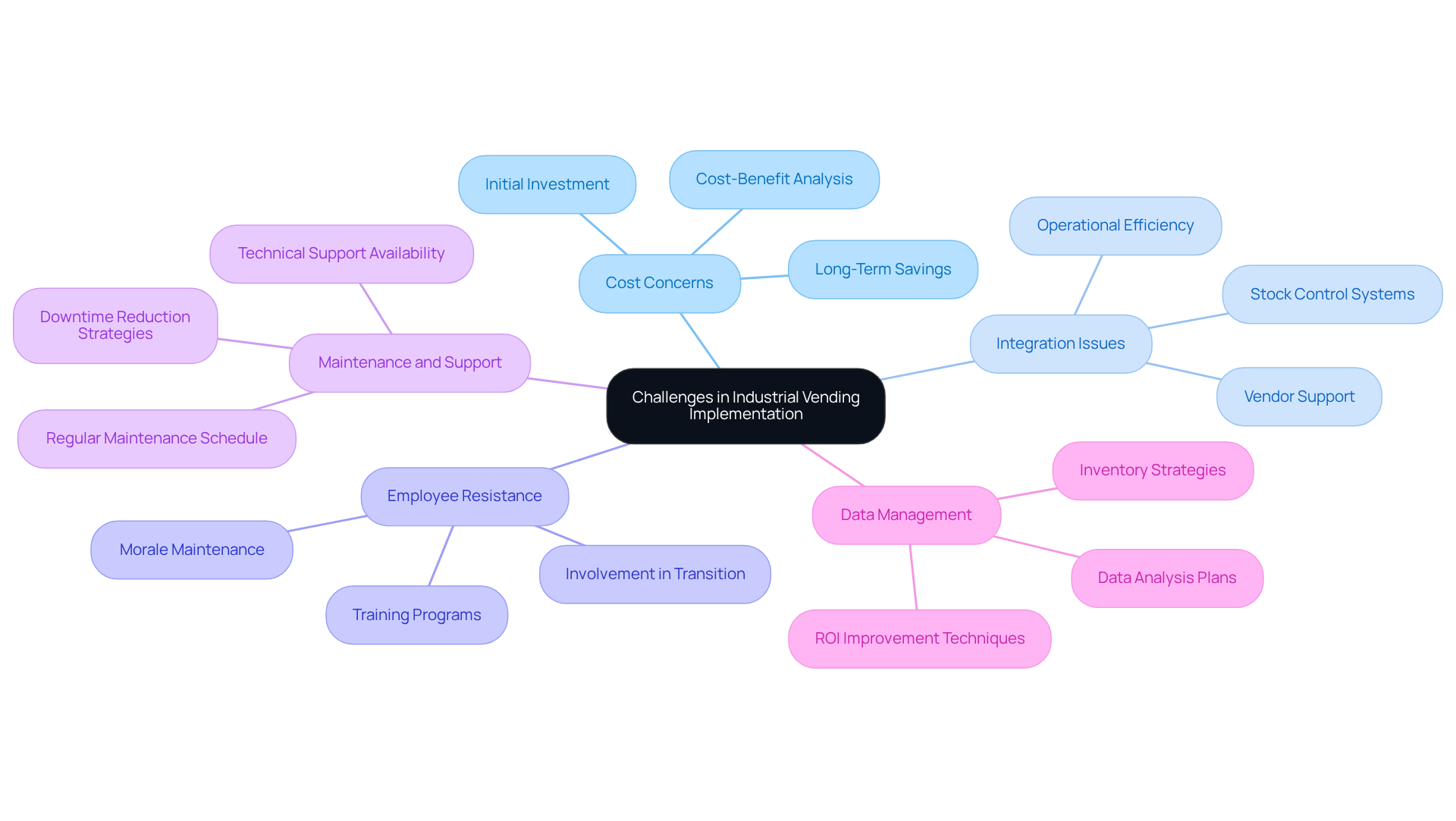

Cost Concerns: First off, the initial cost for those automated dispensers can hit hard, usually ranging from $3,000 to $10,000 each. It’s super important to run a solid cost-benefit analysis to make sure those long-term savings and efficiencies are worth the upfront investment. Just think about it: a well-placed automated dispenser can pull in over $300 a month, which could mean around $5,200 in yearly profits from just one unit!

-

Integration Issues: Now, let’s talk about integration. Connecting those vending machines to your existing stock control systems can be tricky. Teaming up with vendors who offer industrial vending solutions and provide solid support and seamless integration can really help smooth things out. When everything clicks together, you’ll see a boost in operational efficiency and a simpler stock handling process, both of which are enhanced by industrial vending solutions to maximize your profits.

-

Employee Resistance: Change can be tough, especially for employees who are used to the old ways of managing inventory. Getting your team involved early on and providing thorough training can ease those worries and help everyone get on board with the new system. This proactive approach can make the transition smoother and keep morale high.

-

Maintenance and Support: Don’t forget about maintenance! Keeping your equipment in tip-top shape is crucial. Setting up a regular maintenance schedule and having tech support on standby can help you tackle any issues quickly, reducing downtime and keeping productivity flowing.

-

Data Management: Lastly, let’s not overlook the data. When you roll out those vending machines, you’ll gather a ton of valuable information. Having a clear plan for analyzing this data is key to making smart stock decisions and improving operations. By tapping into those insights, you can refine your inventory strategies and boost overall efficiency. Plus, with Vending Village’s hassle-free refunds, managing everything becomes even easier. This, along with smart product selection and pricing strategies, can really ramp up your return on investment (ROI) for vending machine operations.

Conclusion

Implementing industrial vending solutions can really change the game for inventory management and operational efficiency in various industrial settings. Imagine this: by automating the dispensing of tools and supplies, businesses can cut down on downtime and boost productivity. This means employees get immediate access to what they need, which is a win-win! Not only does this streamline operations, but it also enhances accountability and reduces waste. It’s a smart move for companies looking to stay competitive.

Now, here’s the thing: key insights from the article show that:

- A thorough needs assessment

- Careful equipment selection

- Seamless integration with existing systems

- Comprehensive training

are crucial for making this work. Plus, addressing potential challenges like cost concerns, employee resistance, and maintenance needs can really smooth out the transition and lead to greater long-term benefits. The evidence supporting the effectiveness of industrial vending solutions is pretty compelling, with case studies highlighting impressive gains in productivity and cost savings.

So, what does this mean for you? Businesses are encouraged to think about integrating industrial vending solutions as a proactive step toward boosting efficiency and managing resources better. By embracing these best practices, organizations can not only enhance their operational capabilities but also set themselves up for sustained growth in a competitive landscape. Taking action now can lead to significant rewards, ensuring that businesses stay agile and responsive to the demands of their industries.

Frequently Asked Questions

What are industrial vending machines?

Industrial vending machines are automated systems designed to dispense tools, supplies, and personal protective equipment (PPE) in various industrial environments.

What types of industrial vending machines are available?

There are different styles of industrial vending machines, including coil machines and locker systems, tailored to meet specific needs.

How does RFID technology enhance industrial vending machines?

RFID technology allows for automatic tracking of items as they are dispensed, helping to monitor stock levels and reducing the risk of running low on essential supplies.

What are the benefits of using RFID-enabled dispensers in industries like aerospace?

RFID-enabled dispensers provide secure storage and controlled access to certified tools, enhancing quality assurance and minimizing the loss of expensive components.

How does RFID technology contribute to inventory management?

RFID technology aids in real-time data collection on stock levels and usage patterns, leading to smoother operations and better accountability in managing inventory.

What is the projected growth rate for the industrial vending solutions market?

The industrial vending solutions market is projected to grow at a CAGR of 10.1% from 2024 to 2029, driven by technological advancements and the need for efficient supply management.

Why are businesses encouraged to integrate industrial vending solutions?

Integrating industrial vending solutions can boost operational efficiency, improve stock management processes, and ensure reliability in managing operational supplies, tools, and PPE.

List of Sources

- Understand Industrial Vending Machines and Their Functionality

- expertmarketresearch.com (https://expertmarketresearch.com/reports/industrial-vending-machine-market?srsltid=AfmBOoocguBV7d3h5pWjEV9HwoSVZoezk89IHuN-ncOtsXDIU30c75X5)

- marketsandmarkets.com (https://marketsandmarkets.com/Market-Reports/industrial-vending-machine-market-201841752.html)

- consegicbusinessintelligence.com (https://consegicbusinessintelligence.com/industrial-vending-machines-market)

- verifiedmarketresearch.com (https://verifiedmarketresearch.com/product/industrial-vending-machine-market)

- Leverage the Benefits of Industrial Vending Solutions for Enhanced Efficiency

- martinsupply.com (https://martinsupply.com/why-industrial-vending-solutions-are-essential-for-a-productive-workforce)

- generalair.com (https://generalair.com/2019/03/industrial-vending-reduces-cost)

- chocolatepride.com (https://chocolatepride.com/blog/efficiency-industrial-vending-machines-modern-manufacturing)

- sphericalinsights.com (https://sphericalinsights.com/blogs/revolutionizing-inventory-management-the-power-of-industrial-vending-machines)

- autocrib.com (https://autocrib.com/post/7-ways-to-high-roi-with-industrial-vending-4-reductions-in-carrying-costs)

- Implement Industrial Vending Solutions: Best Practices for Success

- Vending Machine Statistics in 2023 - Vending Locator (https://vendinglocator.com/blog/vending-machine-statistics)

- consegicbusinessintelligence.com (https://consegicbusinessintelligence.com/industrial-vending-machines-market)

- toolingintelligence.co.uk (https://toolingintelligence.co.uk/blog/implementing-industrial-vending-machines-best-practices-and-common-pitfalls)

- velocity-smart.com (https://velocity-smart.com/velocity-hub/blog/8-smart-vending-best-practices-for-enhanced-efficiency)

- Address Challenges and Considerations in Industrial Vending Implementation

- How Much Do Vending Machines Cost? (2025) | Naturals2Go (https://naturals2go.com/vending-machine-cost)

- Vending Machine Cost: The Ultimate 2025 Investment Guide (https://widermatrix.com/vending-machine-cost-the-ultimate-2025-investment-guide)

- primidigital.com (https://primidigital.com/vending-machine-cost-analysis-what-you-need-to-know-before-investing)

- What are Startup Costs for Vending Machines? (https://startupfinancialprojection.com/blogs/capex/vending-machines)

- Is It Expensive to Own a Vending Machine? The Complete 2025 Cost Breakdown (https://cottoncandyvending.com/is-it-expensive-to-own-a-vending-machine-the-complete-2025-cost-breakdown)