Introduction

In today's fast-paced manufacturing world, understanding how machines operate is key. Think about it: every day, businesses are looking for ways to run smoother and faster. This article dives into what it takes to set up and run machines efficiently. We’ll cover different types of machines, how to prepare your workspace, and share best practices that can boost your production.

But here’s the thing: as industries push for better efficiency and less downtime, a big question pops up: how can manufacturers make sure their machines not only work well but also keep up with changing demands? Let’s break it down. By exploring this question, we can uncover some solid strategies that might just lead to enhanced productivity and long-term success. So, are you ready to dive in and see how you can make your operations even better?

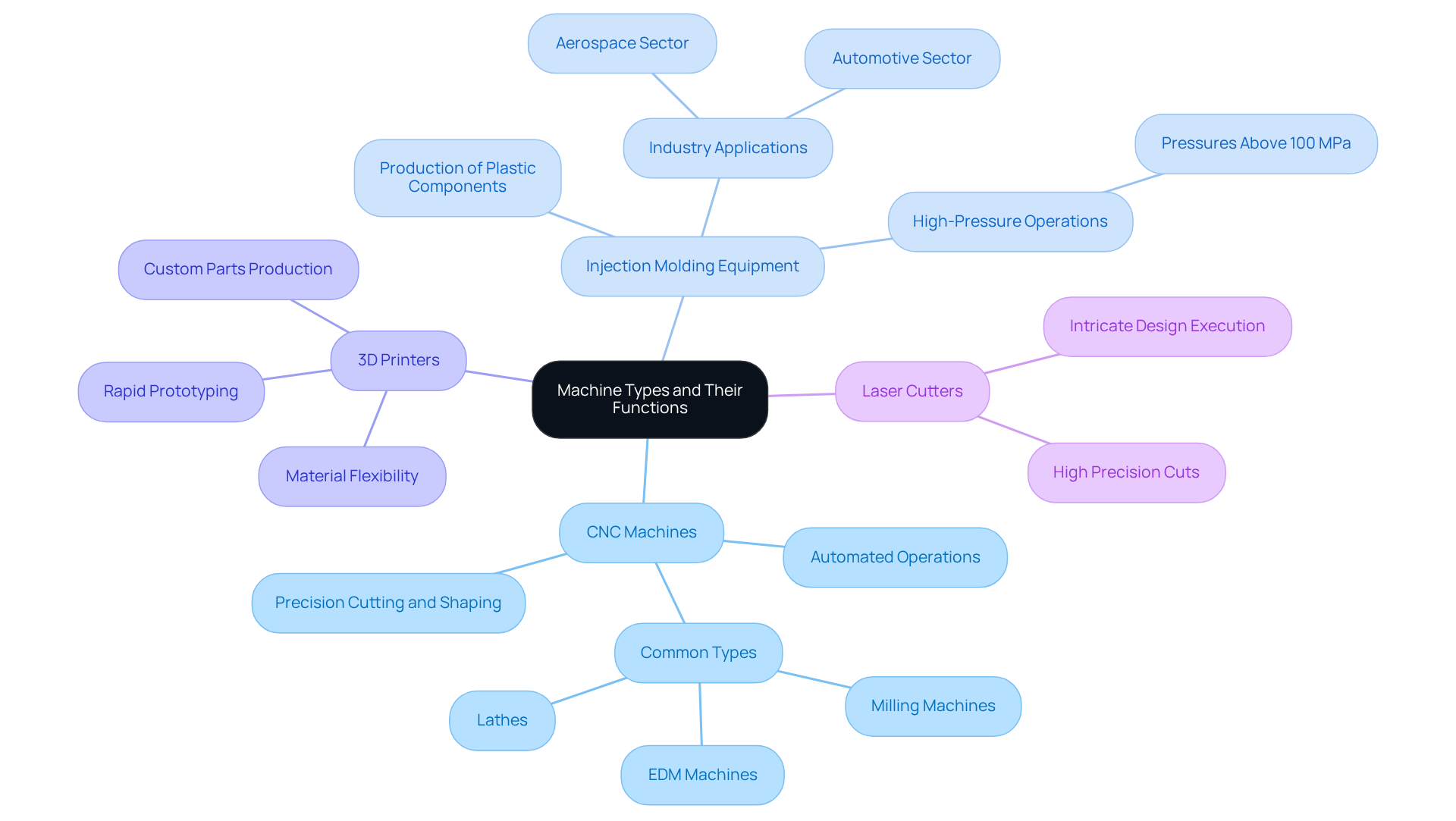

Understand Machine Types and Their Functions

When it comes to set up and operate machines to make products efficiently, understanding the out there is key. Let’s break it down into some essential categories:

- CNC Machines: These are crucial for precision cutting and shaping materials. They automate operations through programmed commands, allowing for intricate designs with tight tolerances. It’s no wonder that CNC devices are a staple in manufacturing—current stats show just how significant they are in the production process.

- Injection Molding Equipment: If you're in the market for producing plastic components, these devices are your go-to. They really shine in industries like automotive and aerospace. By 2025, the injection molding market is expected to hold a strong position, thanks to tech advancements and a growing demand for high-quality plastic parts. Did you know that the automotive sector brings in the highest revenue for injection molding? That just goes to show how essential they are. Plus, high-pressure injection molding equipment operates at pressures above 100 MPa, showcasing their impressive capabilities.

- 3D Printers: These are perfect for rapid prototyping and custom parts. They offer flexibility in design and material use, making it easy to iterate and adjust quickly during production.

- Laser Cutters: If you need to execute intricate designs, laser cutters are fantastic. They provide clean cuts and high precision, which is critical for detailed manufacturing tasks.

Understanding the specifications and capabilities of each type of equipment is vital for being able to set up and operate machines to make products that align with your operational goals. As Hone All puts it, "This type of planning is helpful for rigorous supply chain management." By choosing the right technology, you can boost efficiency and product quality, leading to greater profitability. So, what equipment will you explore next?

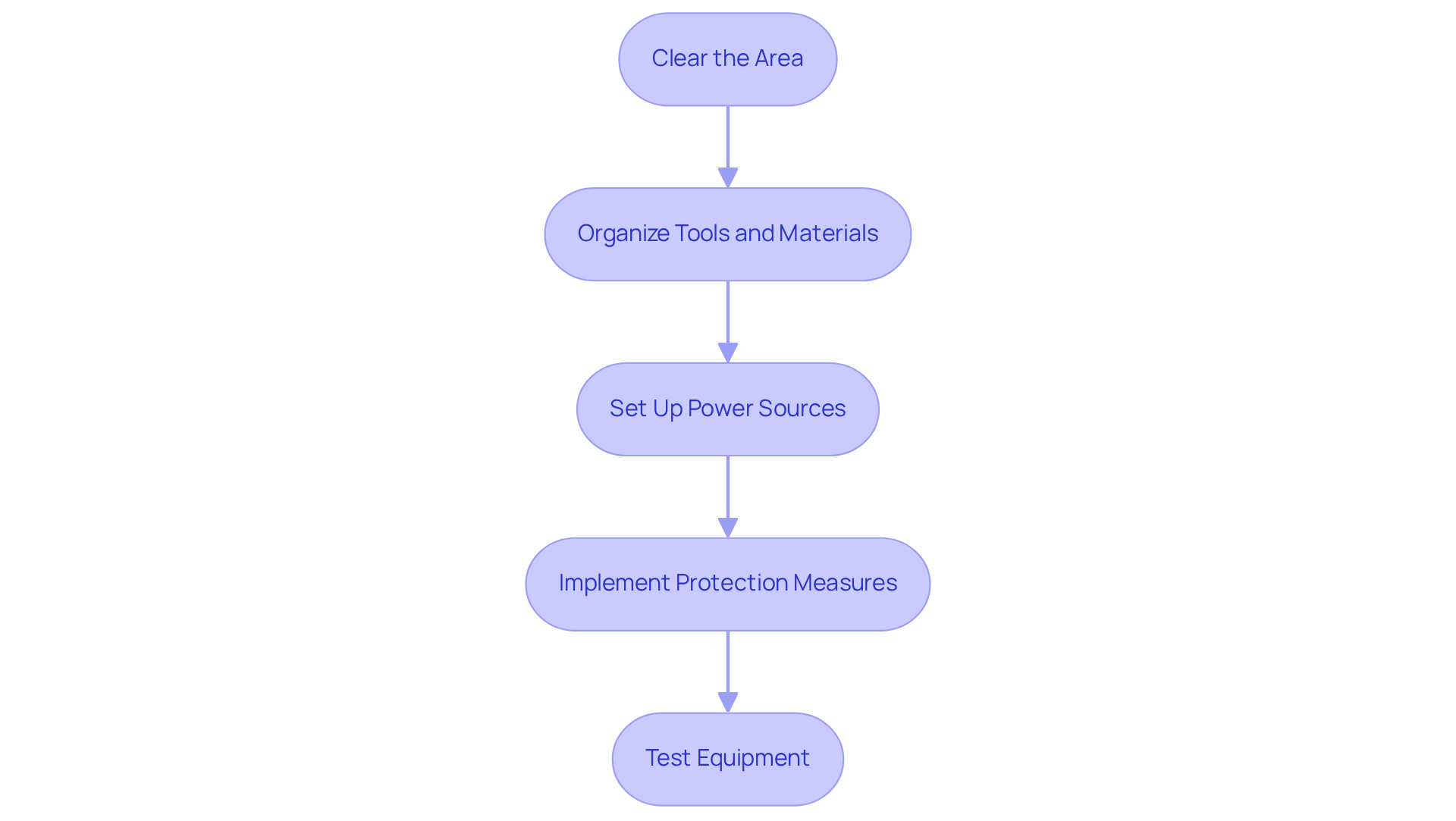

Prepare Your Workspace and Equipment

To get your workspace ready for machine operation, let’s talk about some best practices that really make a difference.

- Clear the Area: First off, keeping your workspace clutter-free is key. A tidy area not only boosts safety but also helps you work more efficiently. When there are , you can really focus on what you need to do. Did you know that 94% of workers feel more productive in a clean environment?

- Organize Tools and Materials: Next, think about how you organize your tools and materials. It’s super helpful to have everything within easy reach. Use shelves, bins, and labeled containers to keep things in order. This way, you spend less time hunting for items, which means a smoother workflow and better efficiency overall.

- Set Up Power Sources: Now, let’s make sure all your machines are hooked up to the right power sources. Check that electrical outlets are easy to get to, so you don’t run into delays when it’s time to operate. Proper power management is crucial for keeping production levels steady.

- Implement Protection Measures: Don’t forget about safety! Install fire extinguishers and first aid kits where they’re easy to access. It’s also important that everyone operating the machines knows the safety protocols. A safe workspace protects your team and builds a culture of responsibility. Plus, keeping things clean can cut down on workplace illness by up to 80% — that’s a big deal!

- Test Equipment: Finally, before you kick off production, do a thorough check on all your equipment. Make sure everything is working correctly and safely. Regular maintenance and testing can save you from costly downtime and potential safety issues.

By following these simple guidelines, you can create a well-organized and safe workspace that not only boosts operational efficiency but also allows you to set up and operate machines to make products effectively.

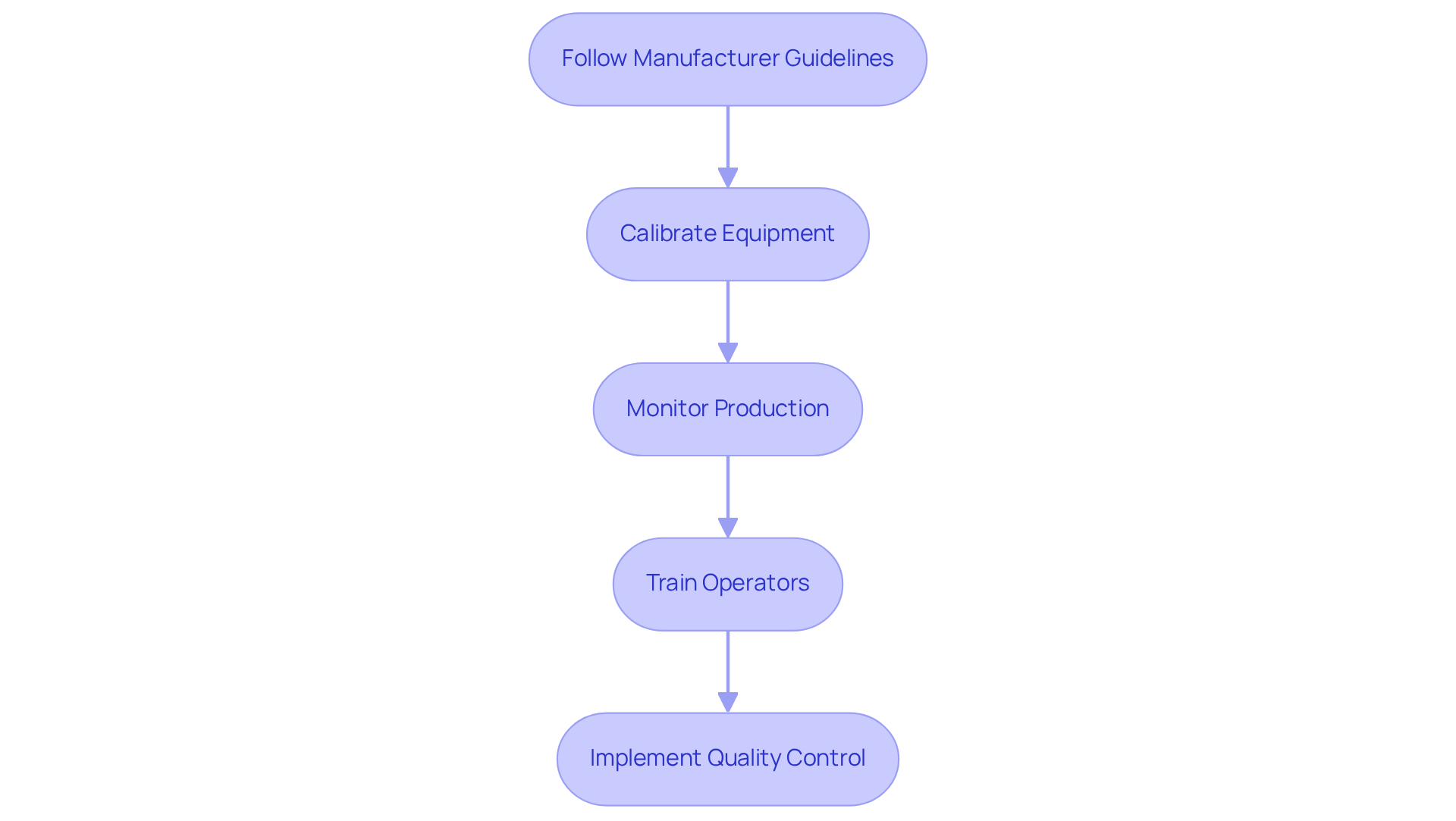

Operate Machines for Optimal Production

When it comes to how to set up and operate machines to make products effectively, there are a few key things to keep in mind.

- First off, follow the manufacturer guidelines. Seriously, sticking to the operating instructions they provide is crucial for both safety and efficiency. It’s like having a roadmap — it’ll help you get where you need to go without any hiccups.

- Next, let’s talk about calibrating your equipment. Regular adjustments are essential to keep everything precise and accurate in manufacturing. Think of it as tuning a musical instrument; it needs to be just right to hit the right notes.

- Don’t forget to monitor production. Keep an eye on metrics like speed, quality, and output. If something seems off, adjust the settings to optimize performance. It’s all about finding that sweet spot.

- Now, here’s the thing: train your operators. Make sure everyone knows how to set up and operate machines to make products and understands the safety protocols. Regular training sessions can really help maintain those high standards. It’s like investing in your team’s skills — the payoff is worth it.

- Finally, let’s not skip on implementing quality control. Establish measures to catch any defects early in the production process. This can significantly , saving you time and resources.

So, there you have it! By following these steps, you’ll be well on your way to operating your machines like a pro.

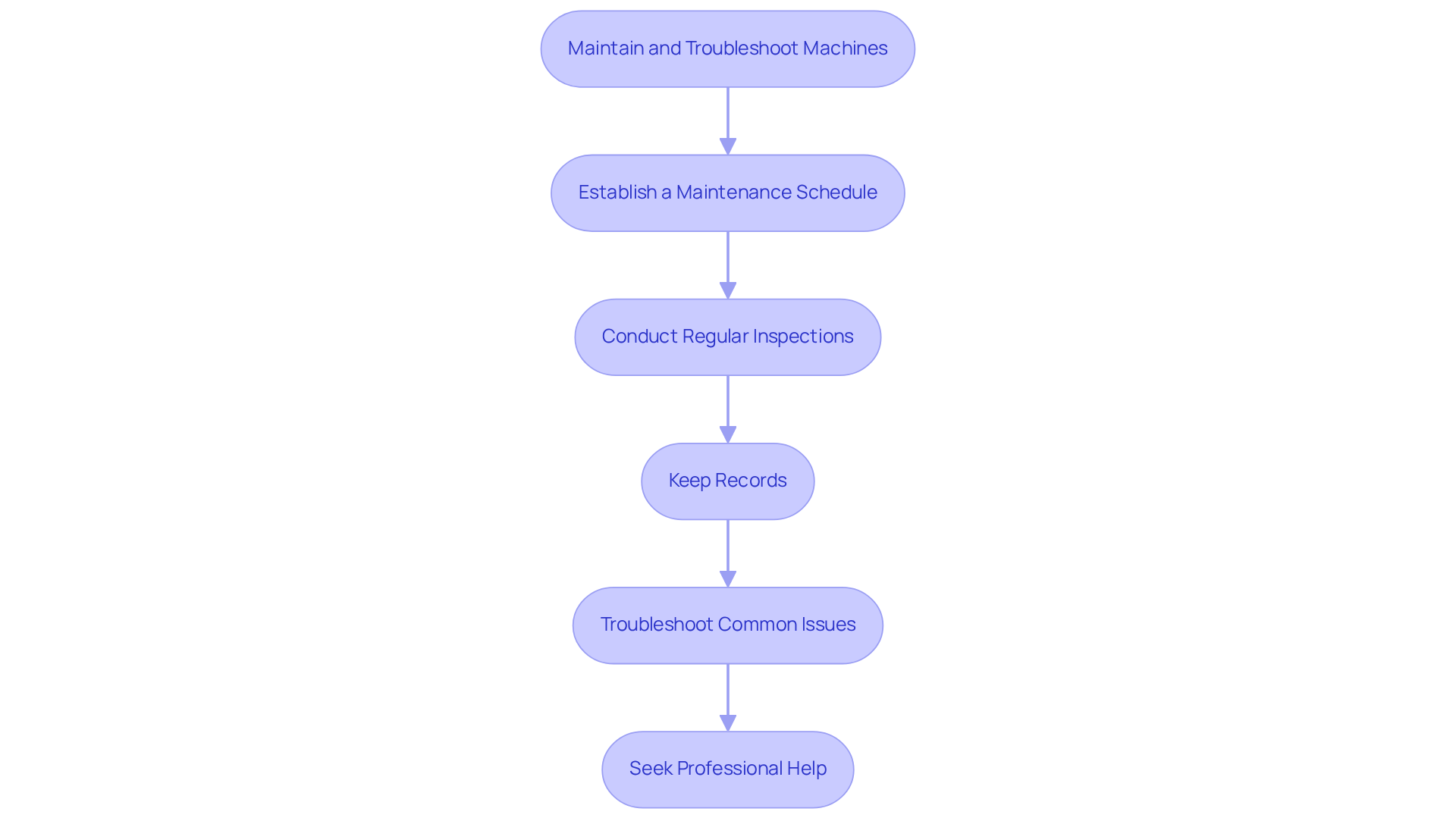

Maintain and Troubleshoot Machines for Longevity

To keep your machines running smoothly and troubleshoot issues effectively, here’s what you can do:

- Establish a Maintenance Schedule: First off, set up a regular maintenance routine based on the manufacturer's guidelines. This helps your equipment . Did you know that consistent upkeep can extend the lifespan of CNC machines by up to 40%? That’s pretty significant, especially since neglect can really shorten their typical lifespan.

- Conduct Regular Inspections: Next, make it a habit to inspect your machines regularly. Look out for signs of wear and tear, like strange noises or vibrations. Keep in mind that aging equipment is nearly three times more likely to cause unexpected downtime compared to operator errors. And that downtime? It can cost manufacturers around $260,000 per hour! So, those regular checks are crucial.

- Keep Records: Don't forget to keep detailed records of all maintenance and repairs. This documentation helps you track how your equipment is doing over time. Plus, it supports proactive maintenance strategies that can save your business 30 to 40% in costs. That’s money back in your pocket!

- Troubleshoot Common Issues: It’s also helpful to know the typical problems your machines might face and how to fix them. For instance, if your CNC isn’t cutting accurately, check the calibration and the condition of the tools. Quick troubleshooting can stop small issues from turning into major breakdowns.

- Seek Professional Help: Finally, if you’re still facing problems after trying these steps, don’t hesitate to call in a professional technician. They can provide a thorough diagnosis and fix the issue. Remember, frequent inspections and timely interventions are key—44% of unplanned downtime in manufacturing is due to aging equipment. As one technician wisely said, "Regular inspections are vital; they not only prevent breakdowns but also ensure that machines operate efficiently and safely.

Conclusion

Setting up and running machines for efficient production isn’t just a task; it’s a whole process that requires a good grasp of the different types of equipment and what they do. When you understand the ins and outs of machines like CNC devices, injection molding tools, 3D printers, and laser cutters, you can really boost production quality and efficiency. This foundational knowledge is key to putting effective practices into play that can elevate your manufacturing game.

Now, let’s talk about some essential steps to get your workspace ready and operate those machines like a pro:

- Keep your area clutter-free. It’s amazing how much smoother things run when tools and materials are organized.

- Stick to the manufacturer’s guidelines and don’t skip those regular maintenance checks.

- Safety and training for operators? Absolutely crucial. They help ensure that everything runs smoothly and efficiently.

- Don’t forget about quality control measures—they’re vital for cutting down waste and maximizing output.

So, here’s the bottom line: mastering machine setup and operation is super important. By embracing best practices in workspace prep, equipment upkeep, and operator training, you can not only ramp up productivity but also extend the life of your machinery. It’s really worth investing time and resources into these areas to build a culture of efficiency and quality in your production processes. As industries change and evolve, staying up-to-date with the latest techniques and technologies will be key to thriving in the competitive manufacturing landscape.

Frequently Asked Questions

What are CNC machines and their primary function?

CNC machines are crucial for precision cutting and shaping materials. They automate operations through programmed commands, allowing for intricate designs with tight tolerances, making them a staple in manufacturing.

What industries benefit from injection molding equipment?

Injection molding equipment is particularly beneficial in industries such as automotive and aerospace, where there is a high demand for producing plastic components.

What is expected for the injection molding market by 2025?

By 2025, the injection molding market is expected to hold a strong position due to technological advancements and a growing demand for high-quality plastic parts.

What is the significance of the automotive sector in injection molding?

The automotive sector brings in the highest revenue for injection molding, highlighting the essential role of these devices in the industry.

What are the advantages of using 3D printers in manufacturing?

3D printers are ideal for rapid prototyping and custom parts, offering flexibility in design and material use, which allows for quick iterations and adjustments during production.

What are laser cutters used for in manufacturing?

Laser cutters are used for executing intricate designs, providing clean cuts and high precision that are critical for detailed manufacturing tasks.

Why is it important to understand the specifications of different machine types?

Understanding the specifications and capabilities of each type of equipment is vital for effectively setting up and operating machines to align with operational goals, boost efficiency, and improve product quality.

List of Sources

- Understand Machine Types and Their Functions

- blog.hone-all.co.uk (https://blog.hone-all.co.uk/honest-cnc-machining-quotes)

- straitsresearch.com (https://straitsresearch.com/report/injection-molding-machines-market)

- maximizemarketresearch.com (https://maximizemarketresearch.com/market-report/cnc-machine-market/126307)

- coherentmarketinsights.com (https://coherentmarketinsights.com/blog/understanding-cnc-machining-quotes-a-beginners-guide-355)

- Prepare Your Workspace and Equipment

- 10 Workplace Hygiene Statistics You Shouldn’t Ignore (https://canadasafetytraining.com/Safety_Blog/workplace-hygiene-statistics.aspx)

- brother.co.uk (https://brother.co.uk/business-solutions/mobile-print-and-label/messy-desk-tidiness-genius-research-statistics)

- Insightful Office Cleaning Statistics & Benefits From Research (https://cstriad.com/office-cleaning-statistics)

- 34 Workplace Productivity Statistics and Trends in 2025 (https://proofhub.com/articles/workplace-productivity-statistics)

- 28 employee productivity statistics that will transform your workflow (https://blog.superhuman.com/employee-productivity-statistics)

- Operate Machines for Optimal Production

- blog.dmsystemsgroup.co.uk (https://blog.dmsystemsgroup.co.uk/calibration-and-its-profound-impact-on-manufacturing-quality-outcomes)

- nagman.com (https://nagman.com/blog/why-do-manufacturers-need-calibration)

- advancedtech.com (https://advancedtech.com/blog/why-manufacturers-should-care-about-calibration)

- The Top 200 Manufacturing & Operations Quotes (https://praxie.com/top-business-operations-manufacturing-quotes)

- damotech.com (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Maintain and Troubleshoot Machines for Longevity

- worktrek.com (https://worktrek.com/blog/manufacturing-maintenance-statistics)

- caisoft.com (https://caisoft.com/resources/manufacturing-maintenance-statistics)

- gocodes.com (https://gocodes.com/equipment-maintenance-statistics)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- Maintenance statistics and trends 2025 • Infraspeak Blog (https://blog.infraspeak.com/maintenance-statistics-trends-challenges)