Overview

So, you’ve got a pop machine that’s acting up? Don’t worry; you’re not alone! This article lays out some essential steps for property managers like you to tackle those pesky vending machine issues. We’ll chat about the tools you need, common problems you might face, and how to diagnose and fix them.

First off, let’s talk tools. Having the right equipment on hand makes all the difference. You’ll want to gather everything you need before diving into repairs. Once you’re equipped, we’ll walk through troubleshooting and repair processes that will help you get that machine back in action.

By the end of this guide, you’ll feel confident tackling any issues that come up. Think of it as arming yourself with the knowledge to keep those vending machines running smoothly for your customers. After all, a reliable pop machine can make a big difference in customer satisfaction! So, let’s get started and ensure you’re ready to handle whatever comes your way.

Introduction

Dealing with vending machine maintenance can feel overwhelming for property managers, especially when a pop machine goes on the fritz. But here's the thing: knowing the basic steps for repairs not only saves you time but also keeps your customers happy. What if I told you that fixing these common issues might be easier than you think?

In this guide, we’ll dive into the essential tools, the frequent problems you might encounter, and straightforward, step-by-step instructions to tackle pop machine repairs. With this knowledge, you’ll be empowered to keep your machines running smoothly and efficiently. So, let’s break it down together!

Gather Essential Tools and Materials for Repair

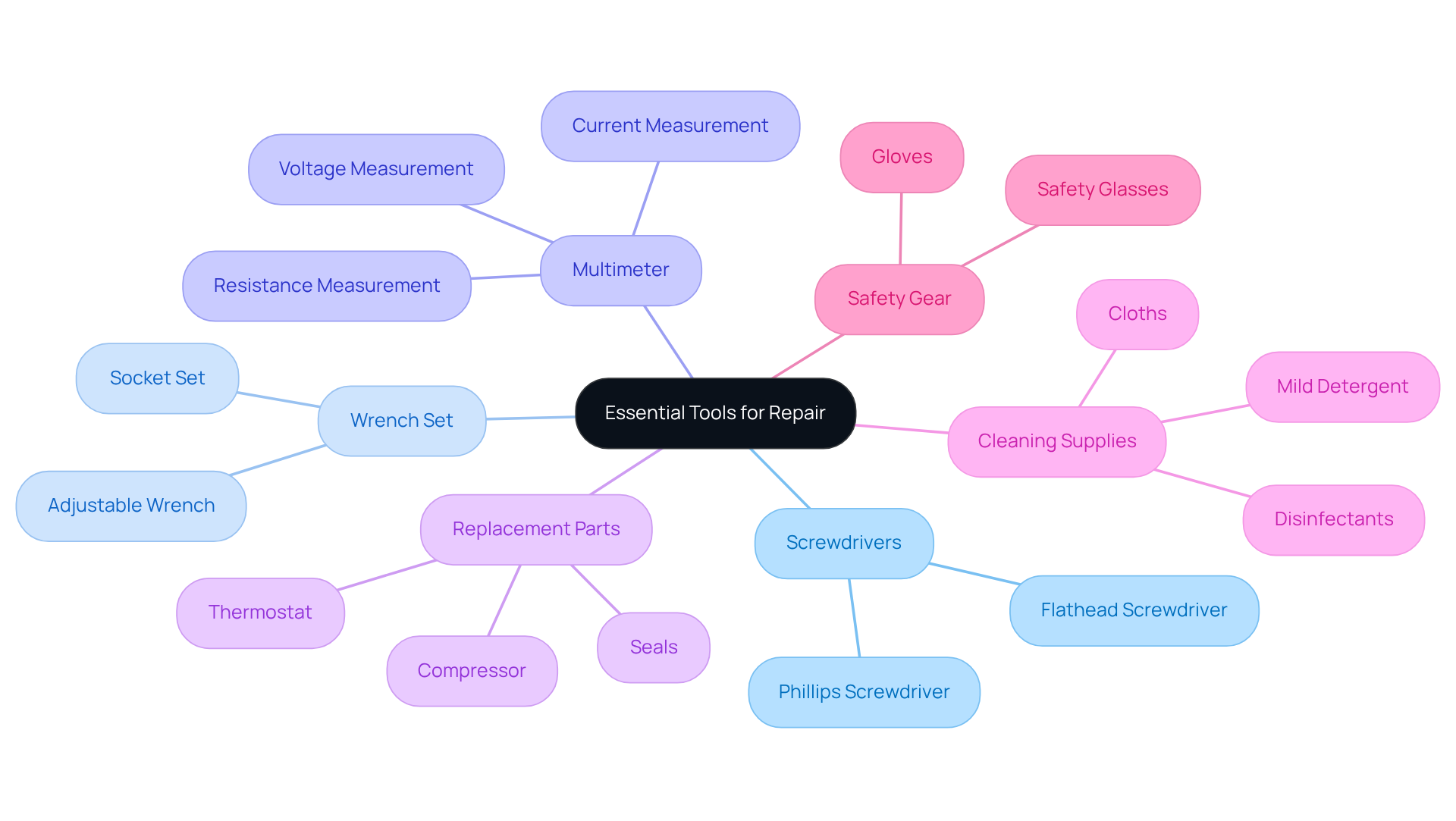

Before diving into how to fix a pop machine, let’s make sure you’ve got the right tools and materials on hand. It’ll make everything smoother!

First up, you’ll need some screwdrivers. A mix of is key for getting those panels off and reaching the inner workings.

Next, grab an adjustable wrench set. This will help you tighten or loosen bolts and nuts, keeping everything nice and secure.

You can’t forget about a multimeter. This handy tool is a must for spotting electrical issues since it measures voltage, current, and resistance. It’ll help you find the problem quickly.

Depending on your specific machine, you might also need replacement parts, like a new compressor, thermostat, or seals. Always check the manufacturer’s specs to make sure you’re getting the right fit.

And don’t overlook cleaning supplies! Having cloths, mild detergent, and disinfectants handy will help you keep things tidy during the repair—super important for both functionality and hygiene.

Lastly, make sure you have your safety gear ready. Wearing gloves and safety glasses will protect you from sharp edges and electrical hazards.

Having these tools and materials ready not only makes the repair process smoother but also is essential when learning how to fix a pop machine, as it cuts down on interruptions. So, let’s get to it and keep those vending machines running like a charm!

Identify Common Problems with Pop Machines

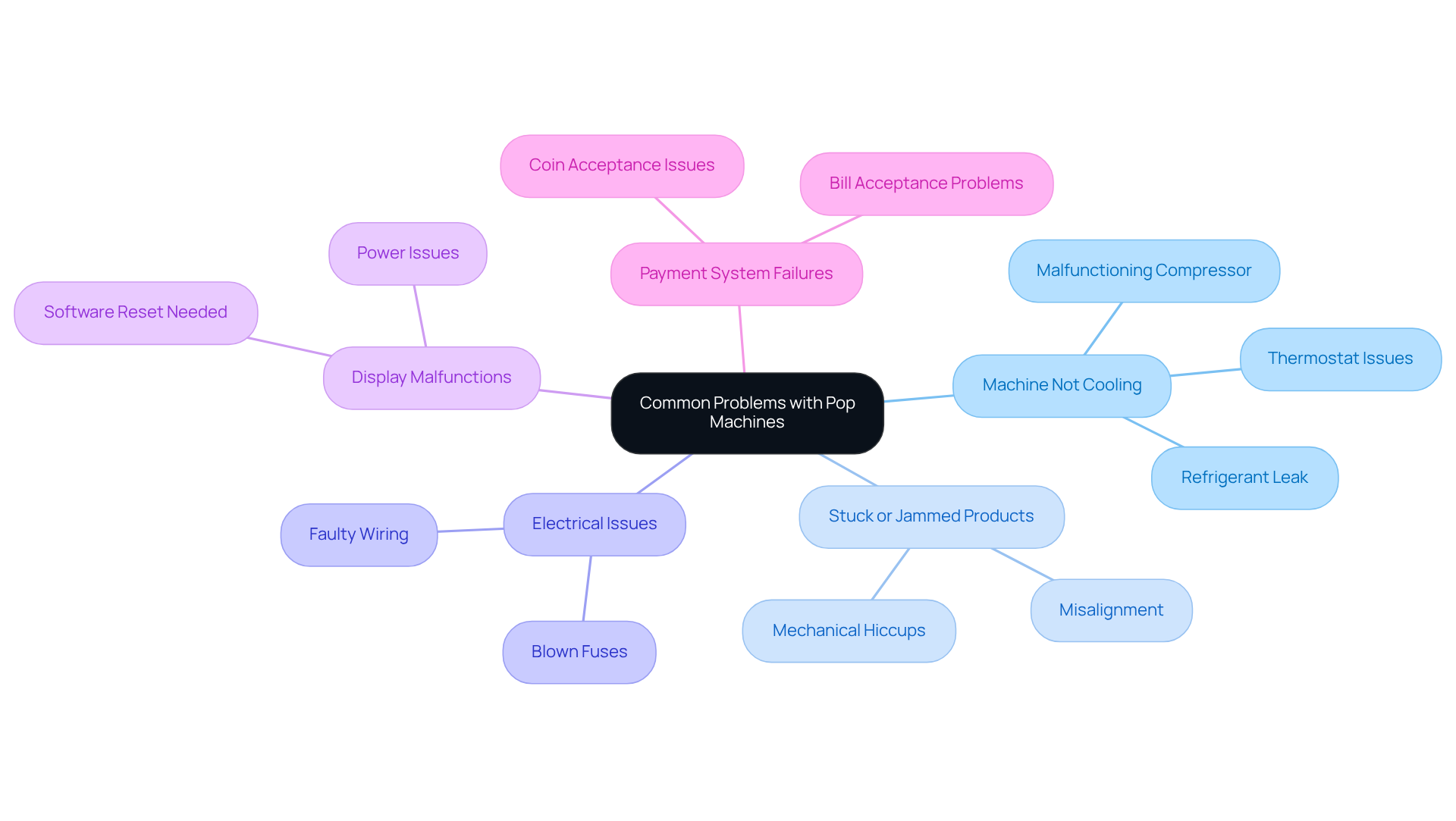

Let’s face it, understanding how to fix a pop machine can be a bit tricky sometimes. Here are some common problems you might run into:

- Machine Not Cooling: This could be a sign of a malfunctioning compressor, thermostat, or maybe there’s a refrigerant leak.

- Stuck or Jammed Products: Ever had a drink get stuck? That’s usually due to misalignment or some mechanical hiccup in the dispensing mechanism.

- Electrical Issues: If you’re dealing with blown fuses or faulty wiring, that could keep the machine from working at all.

- Display Malfunctions: If the digital display is acting up, it might suggest a power issue or that it needs a software reset.

- Payment System Failures: Problems with accepting coins or bills can really frustrate customers and lead to lost sales.

By keeping an eye out for these frequent challenges, you can focus your troubleshooting efforts on how to fix a pop machine where they’re needed most. This way, you’ll save both time and resources, and keep your customers happy!

Diagnose Issues Step-by-Step

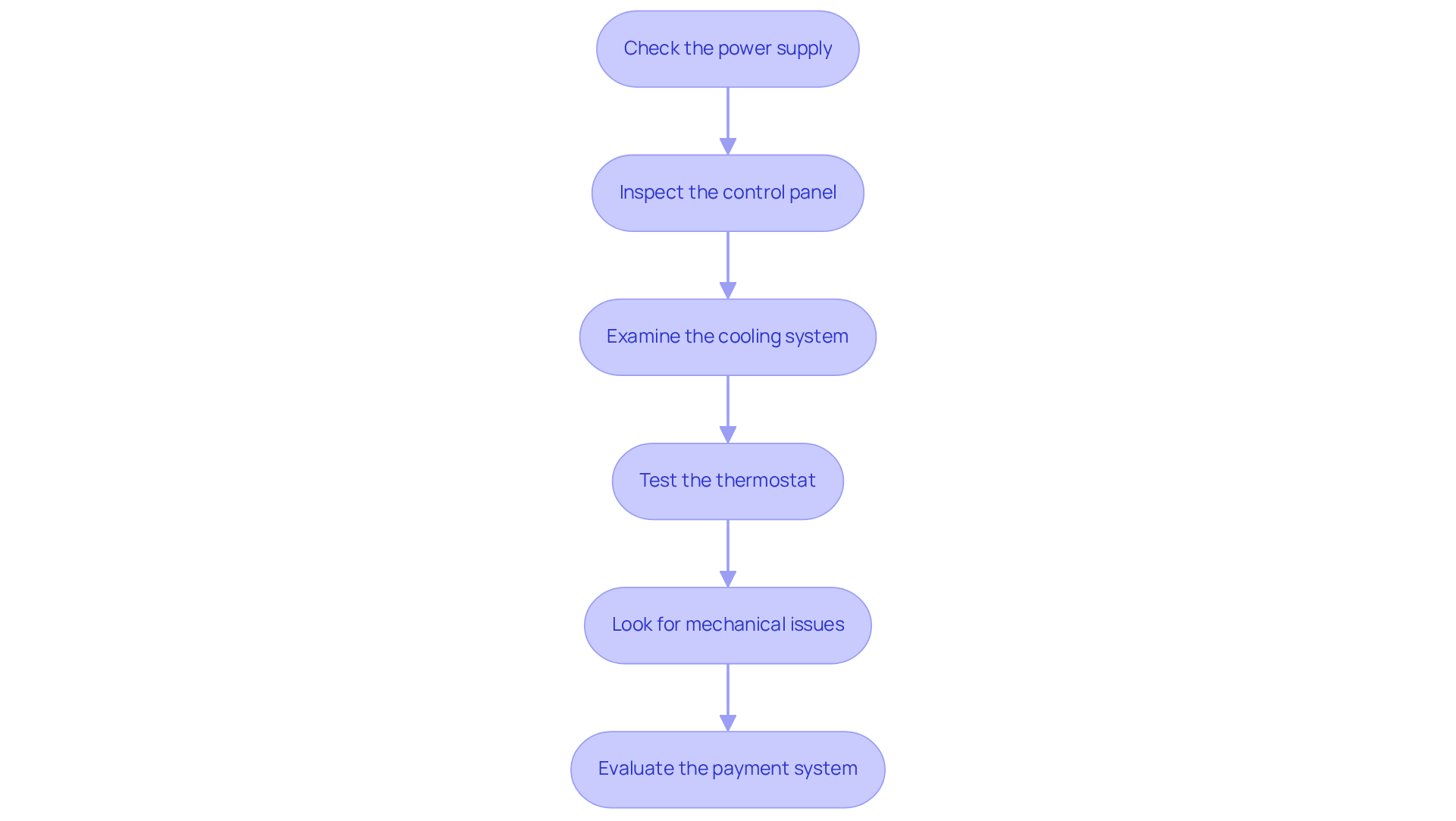

Are you dealing with a pop machine that’s not working and wondering how to fix a pop machine? We’ve all been there, and it can be a real hassle. But don’t worry! Here’s a straightforward guide to help you get things back on track.

- Check the power supply. Make sure the machine is plugged in and that the outlet is working. A quick voltage check with a multimeter can save you a lot of headaches, as power issues are often the culprits behind these problems.

- Inspect the control panel. Are there any error codes or warning lights? Grab the user manual and see what those indicators mean—they can give you immediate insights into what’s going on.

- Examine the cooling system. Open up the machine and take a look at the compressor and evaporator coils. Any frost buildup or strange noises? That could point to cooling issues that might affect your products.

- Test the thermostat. Using a multimeter, check its resistance to ensure it’s functioning properly. A faulty thermostat can lead to improper cooling and spoilage, which is the last thing you want.

- Look for mechanical issues. Check the dispensing mechanism for any jams or misalignments. Give it a manual test to see if it operates smoothly. Product jams are a common complaint, so regular upkeep here can really help.

- Evaluate the payment system. Test those to make sure they’re working as they should. A little cleaning can go a long way in removing debris that might block their operation. After all, payment system failures can frustrate customers.

By following these steps, you will understand how to fix a pop machine head-on. Remember, regular maintenance is key to preventing common vending problems and keeping your customers satisfied. So, roll up your sleeves and get to it—you’ve got this!

Execute Repairs with Clear Instructions

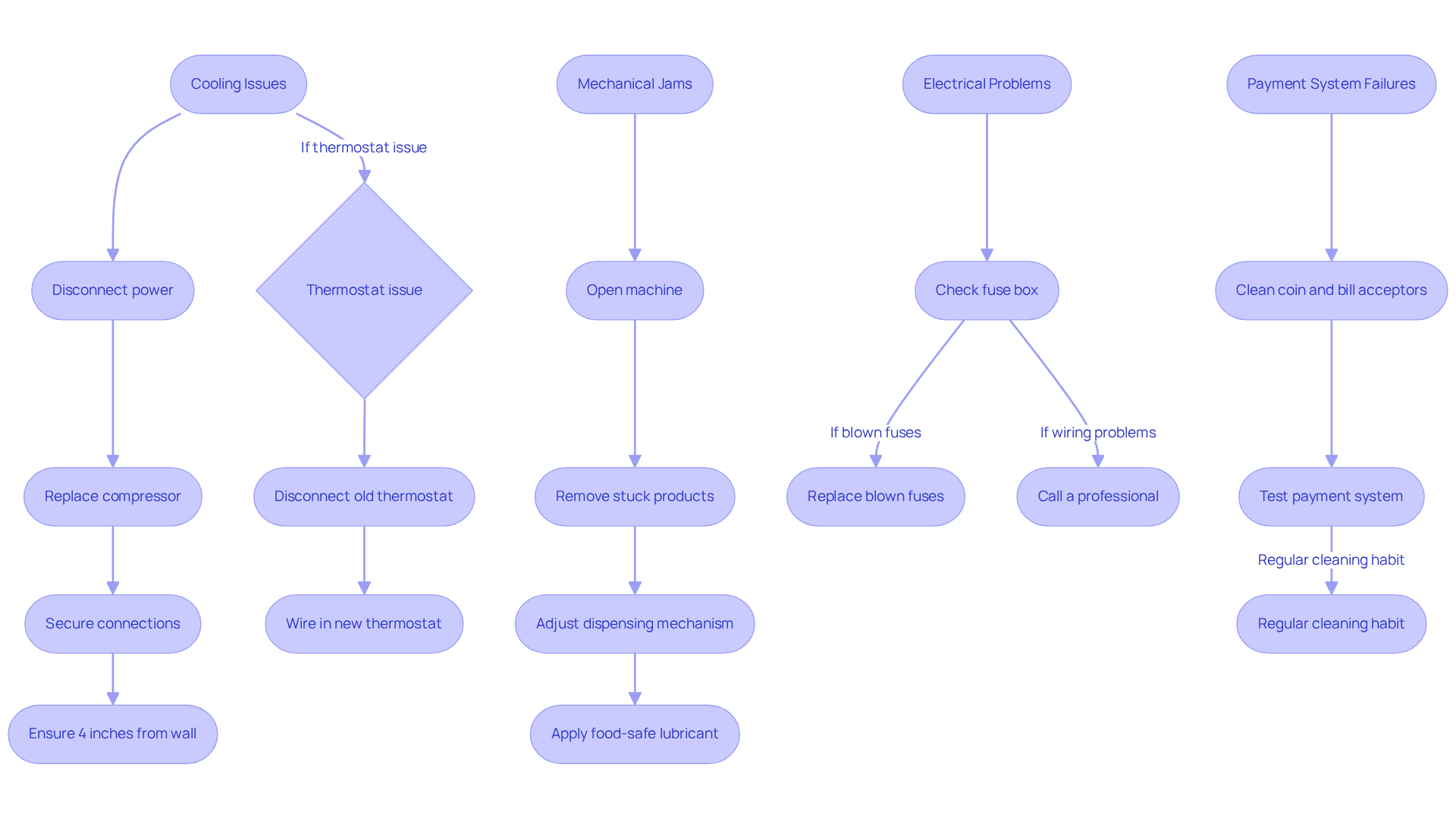

If you’re dealing with pop machines, here’s a straightforward guide just for property managers on how to fix a pop machine effectively.

Cooling Issues:

- First off, if the compressor is acting up, the first step is to disconnect the power.

- Then, swap out the old compressor for a new one, following the manufacturer’s instructions.

- Make sure all connections are secure to keep everything running smoothly.

- And don’t forget, vending units should be at least four inches away from the wall to allow for proper airflow—this is key to preventing overheating.

- Now, if the thermostat is giving you trouble, it’s a simple fix.

- Just disconnect the old thermostat and wire in the new one, ensuring those connections are nice and tight.

- When it comes to mechanical jams, open up the machine and gently remove any stuck products.

- You might need to adjust the dispensing mechanism to make sure everything is aligned and working properly.

- A little food-safe lubricant on the moving parts can go a long way in preventing future jams, which keeps your service smooth and customers happy.

Electrical Problems:

- Got electrical issues? Start by checking the fuse box.

- If you find any blown fuses, replace them with new ones of the same rating.

- This quick fix can often get the power back on in no time.

- If you run into wiring problems, it’s best to call in a pro to avoid any more headaches.

Payment System Failures:

- To keep the payment systems running smoothly, make it a habit to clean the coin and bill acceptors with a soft cloth.

- This helps remove any debris that could be causing issues.

- After cleaning, test the system to ensure everything’s working as it should.

- A good rule of thumb is to clean those money slots every time you collect bills and coins to prevent any coin jams.

By following these simple steps on how to fix a pop machine, you can maintain your pop dispensers in great shape, ensuring they function well and contribute positively to workplace productivity and morale.

As RSL puts it, "Employee wellbeing is no longer a 'nice to have' — it’s a strategic advantage."

This really highlights how important it is to in the workplace.

Test the Machine After Repairs

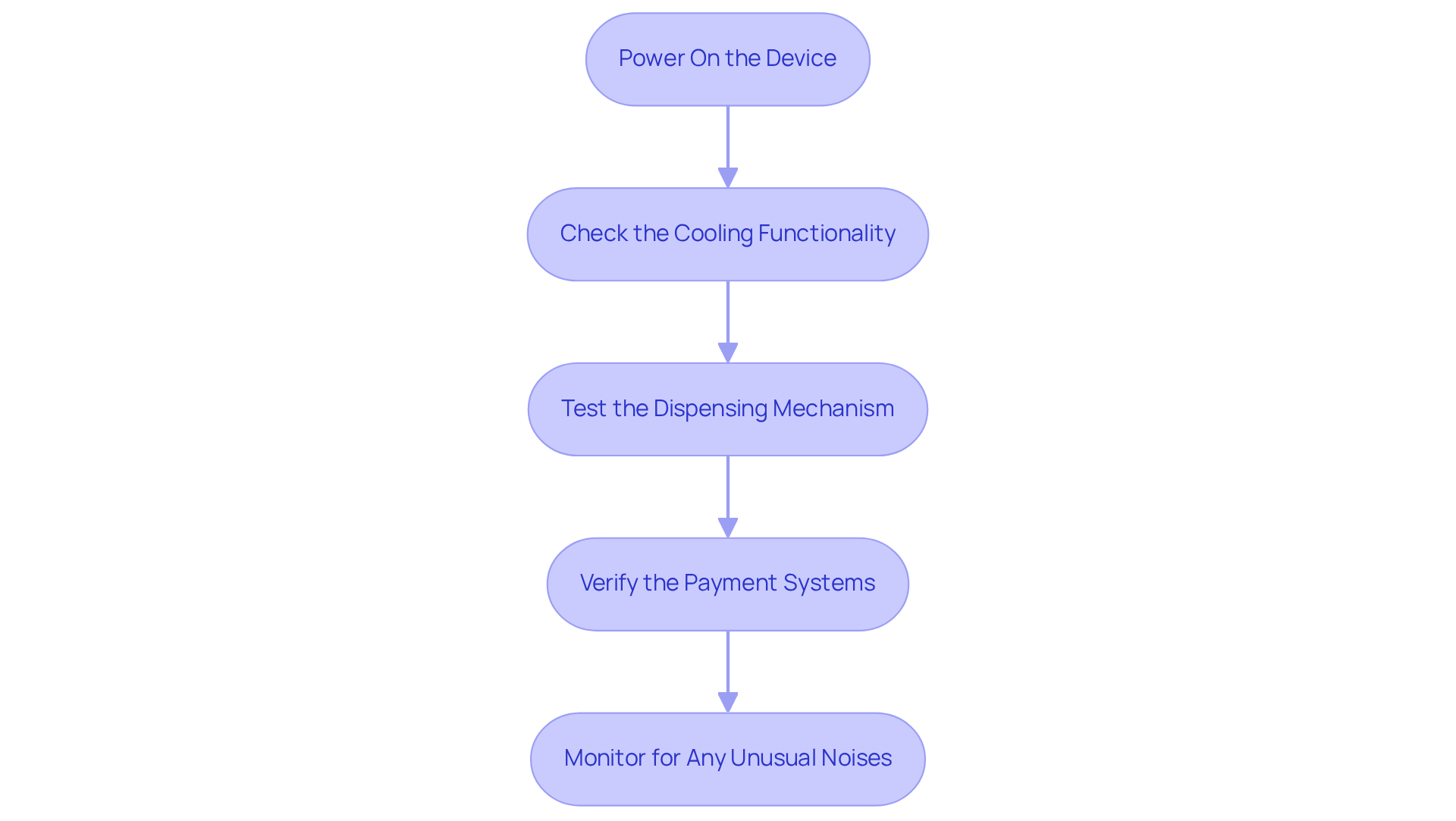

Once you've wrapped up those repairs, it's time to test the pop machine to see how to fix a pop machine and ensure everything's working like it should.

First off, power on the device. Just plug it back in and turn it on. Keep an eye on the control panel for any pesky error messages.

Next, let’s check the cooling functionality. Give the machine a few hours to do its thing and see if it’s cooling effectively. A quick thermometer check on the internal temperature can help you out here.

Now, it’s time to test the dispensing mechanism. Run a few test products through and make sure they come out smoothly—no jams allowed!

Don’t forget to verify the payment systems. Insert different coins and bills to see if those acceptors are doing their job.

Lastly, monitor for any unusual noises. If you hear anything strange, that could be a sign of underlying issues.

By thoroughly testing your machine after repairs, you’re effectively learning how to fix a pop machine and setting yourself up for success. This way, you can ensure your pop machines are ready to roll by , providing reliable service for your customers.

Conclusion

Understanding how to fix a pop machine is super important for property managers who want their vending machines to run smoothly and keep customers happy. By following a few simple steps—like gathering the right tools, diagnosing issues, and making repairs—you’ll see that staying ahead of maintenance can stop many common problems in their tracks and really boost the machines' performance.

Let’s face it, we all know how frustrating it can be when a vending machine doesn’t work right. That’s why it’s crucial to spot frequent issues like cooling failures, mechanical jams, and payment system glitches. Each part of the troubleshooting process, from checking the power supply to testing the dispensing mechanism, is key to figuring out what’s wrong and fixing it. With the right tools and a straightforward approach, you can take on repairs with confidence and keep your machines in top shape.

Here’s the thing: keeping your vending machines running isn’t just about fixing things when they go wrong. It’s about building a reliable service that keeps customers satisfied and boosts workplace productivity. By following these practices, you can make sure your pop machines are a valuable asset, enhancing the experience for everyone who uses them. A little regular upkeep and attention to detail can turn a simple vending machine into a dependable source of refreshment, highlighting just how important effective management is in property maintenance.

Frequently Asked Questions

What essential tools and materials are needed for repairing a pop machine?

You will need a mix of flathead and Phillips screwdrivers, an adjustable wrench set, a multimeter, potential replacement parts (like a compressor, thermostat, or seals), cleaning supplies (cloths, mild detergent, and disinfectants), and safety gear (gloves and safety glasses).

Why is a multimeter important for fixing a pop machine?

A multimeter is essential for spotting electrical issues as it measures voltage, current, and resistance, helping you quickly identify the problem.

What common problems can occur with pop machines?

Common problems include the machine not cooling, stuck or jammed products, electrical issues (like blown fuses or faulty wiring), display malfunctions, and payment system failures.

What might cause a pop machine to not cool properly?

A malfunctioning compressor, thermostat issues, or a refrigerant leak could be signs that the machine is not cooling properly.

How can I troubleshoot a stuck or jammed product in a pop machine?

Stuck or jammed products are usually caused by misalignment or mechanical issues in the dispensing mechanism.

What should I do if the digital display on the pop machine is malfunctioning?

A malfunctioning digital display may indicate a power issue or the need for a software reset.

What are some signs of payment system failures in a pop machine?

Problems with accepting coins or bills can lead to payment system failures, which can frustrate customers and result in lost sales.

List of Sources

- Gather Essential Tools and Materials for Repair

- Master Maintenance with These Vending Machine Tools and Techniques (https://amequipmentsales.com/master-vending-machine-maintenance-tools-techniques?srsltid=AfmBOor6SnZ2Kf5A2cSSdwjKfk1P-xCp_GjX4pXTCdgfFPfj_PEsI1R2)

- Vending Operator Basic Tools (https://amequipmentsales.com/top-vending-tools-basic-toolkit?srsltid=AfmBOoq8s2P1HoJvGrz1ULZmpY-ngmP4-zW-08VzMfNEFLlpGrcT2GP7)

- 49-2011.00 - Computer, Automated Teller, and Office Machine Repairers (https://onetonline.org/link/summary/49-2011.00)

- What Are the Best Tools for Vending Machine Maintenance? (https://linkedin.com/pulse/what-best-tools-vending-machine-maintenance-vending-machines-ie-hwbpc)

- Identify Common Problems with Pop Machines

- Nayax (https://allcloud.io/case_studies/nayax)

- The Challenges and Solutions to Vending Machine Maintenance (https://toolingintelligence.co.uk/blog/the-challenges-and-solutions-to-vending-machine-maintenance)

- Common Problems With Vending Machines And How To Fix Them (https://dropshipvending.com/blogs/vending-machine-blogs/common-problems-with-vending-machines-and-how-to-fix-them)

- Diagnose Issues Step-by-Step

- Restore Your Broken Vending Machine: A Step-by-Step Guide (https://blog.vendingvillage.com/restore-your-broken-vending-machine-a-step-by-step-guide)

- Troubleshooting Common Vending Machine Issues (https://amequipmentsales.com/troubleshooting-common-vending-machine-issues?srsltid=AfmBOoqJNxIwvqAJxMLdJ5ABPuk3PbxcEns_NyhbRFLxJGvqqGhv7WVW)

- Common Problems With Vending Machines And How To Fix Them (https://dropshipvending.com/blogs/vending-machine-blogs/common-problems-with-vending-machines-and-how-to-fix-them)

- Vending Machine Troubleshooting Guide (https://webstaurantstore.com/guide/993/vending-machine-troubleshooting-guide.html?srsltid=AfmBOoq8T-yshQcHrVpUe49N195xvAlJaWRzdbzM_ZDhPemtGcUbkPc3)

- Execute Repairs with Clear Instructions

- Tips for DIY Vending Machine Repair | RSL (https://refreshmentsystems.co.uk/tips-for-diy-vending-machine-repair?srsltid=AfmBOorCerea14U1JuXOxWww4MAmueNRGVc-O1Sm8D2hm5ZYMktHX4Jb)

- An Owner’s Guide to Vending Machine Service and Repair | TCN Vending (https://tcnvending.com.au/owners-guide-vending-machine-service-repair)

- Test the Machine After Repairs

- Vending Machine Maintenance (Step-by-Step Guide) - FieldEx (https://fieldex.com/en/blog/vending-machine-maintenanceguide)

- Vending Machine Operation & Repair: Expert Q&A Guide (https://justanswer.com/appliance/odofp-purchase-vending-machines-don-t.html)

- Maintaining Vending Machines for Profitability (https://worldwidevending.com.au/2025/01/08/maintaining-vending-machine)

- Bethlehem supermarket's water vending machine reopens after testing shows no bacteria (https://lehighvalleynews.com/bethlehem/bethlehem-supermarkets-water-vending-machine-reopens-after-testing-shows-no-bacteria)

- Vending Machine Maintenance: Common Issues and How to Fix Them (https://linkitsoft.com/best-vending-machine-maintenance-services)