Overview

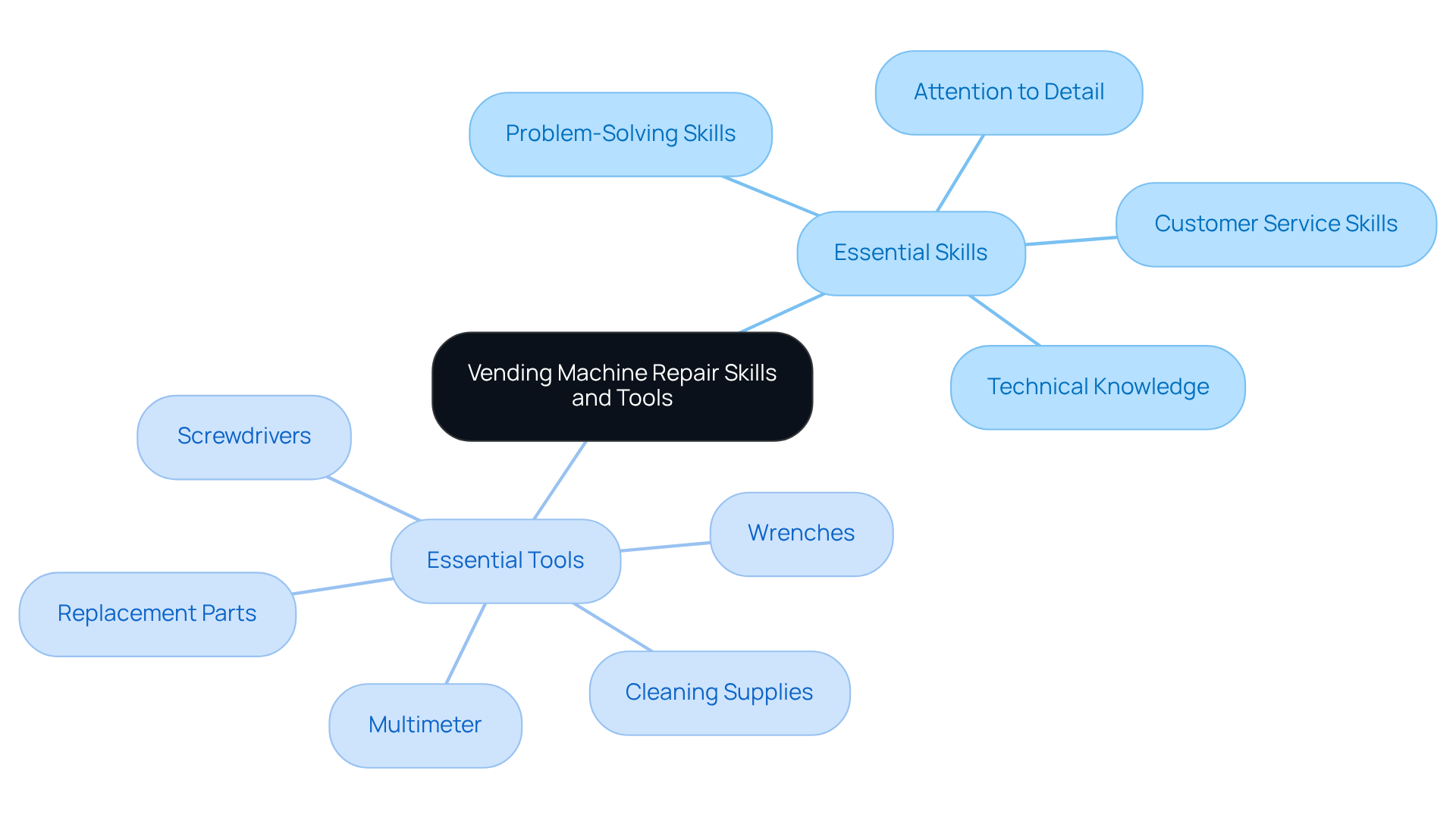

So, you want to become a successful vending machine fixer? That’s a great choice! To get there, you’ll need to pick up some essential skills. Think about:

- Technical know-how

- Problem-solving abilities

- A dash of customer service skills

And don’t forget the right tools—screwdrivers, multimeters, and cleaning supplies are your best friends in this line of work.

Here’s the thing: routine maintenance and effective troubleshooting techniques are key. They’ll help ensure those vending machines run smoothly and keep customers happy. So, take a moment to think about how you can integrate these practices into your routine. You’re on your way to mastering this trade!

Introduction

Becoming a vending machine fixer is a pretty cool gig that mixes technical skills with customer service — and guess what? It's a skill that's really in demand these days. In this guide, we’re going to dive into the essential skills, tools, and techniques you’ll need to shine in this niche field. Think of it as sharing some valuable insights for anyone looking to step into this role.

But here’s the thing: with vending technology evolving so fast, it raises an important question. What challenges are out there for those of us wanting to master vending machine repair? And how can we stay ahead of the game? Let’s break it down together.

Understand Essential Skills and Tools for Vending Machine Repair

To really shine as a dispenser technician, you need to get a handle on some key skills and have the right tools at your fingertips. Let’s break it down:

Essential Skills:

- Technical Knowledge: You’ve got to understand how work — think electrical systems, motors, and sensors.

- Problem-Solving Skills: It’s all about troubleshooting. You want to be able to think critically and come up with solutions to different issues that pop up.

- Attention to Detail: Precision matters! When diagnosing problems and making repairs, being thorough ensures everything runs smoothly.

- Customer Service Skills: Good communication with clients is key. Understanding what they need can really boost the quality of your service.

- Screwdrivers: A solid set of Phillips and flathead screwdrivers is a must for getting into those machine panels.

- Multimeter: This handy tool helps you test electrical components and troubleshoot common electrical issues in vending machines.

- Wrenches: You’ll need adjustable wrenches to tighten or loosen bolts during maintenance.

- Replacement Parts: Keeping a stash of common parts like belts, motors, and sensors can speed up repairs and cut down on downtime.

- Cleaning Supplies: Regularly cleaning machines, especially coin and bill acceptors, is crucial. It helps prevent malfunctions from dust and grime, plus it makes the machines look better and work more effectively.

Now, let’s talk about common problems you might face. Being aware of issues like cooling failures, mechanical jams, and payment system failures is super important for effective troubleshooting. Catching these problems early can save you from bigger headaches later on.

And don’t forget about record keeping! Keeping accurate records of maintenance and repairs is vital for accountability and tracking performance. This helps you make informed decisions about future maintenance and replacements.

By equipping yourself with these skills and tools, you’ll be ready to tackle the challenges faced by a vending machine fixer. This way, you can ensure that everything runs smoothly and meets your customers' expectations.

Diagnose Common Vending Machine Problems

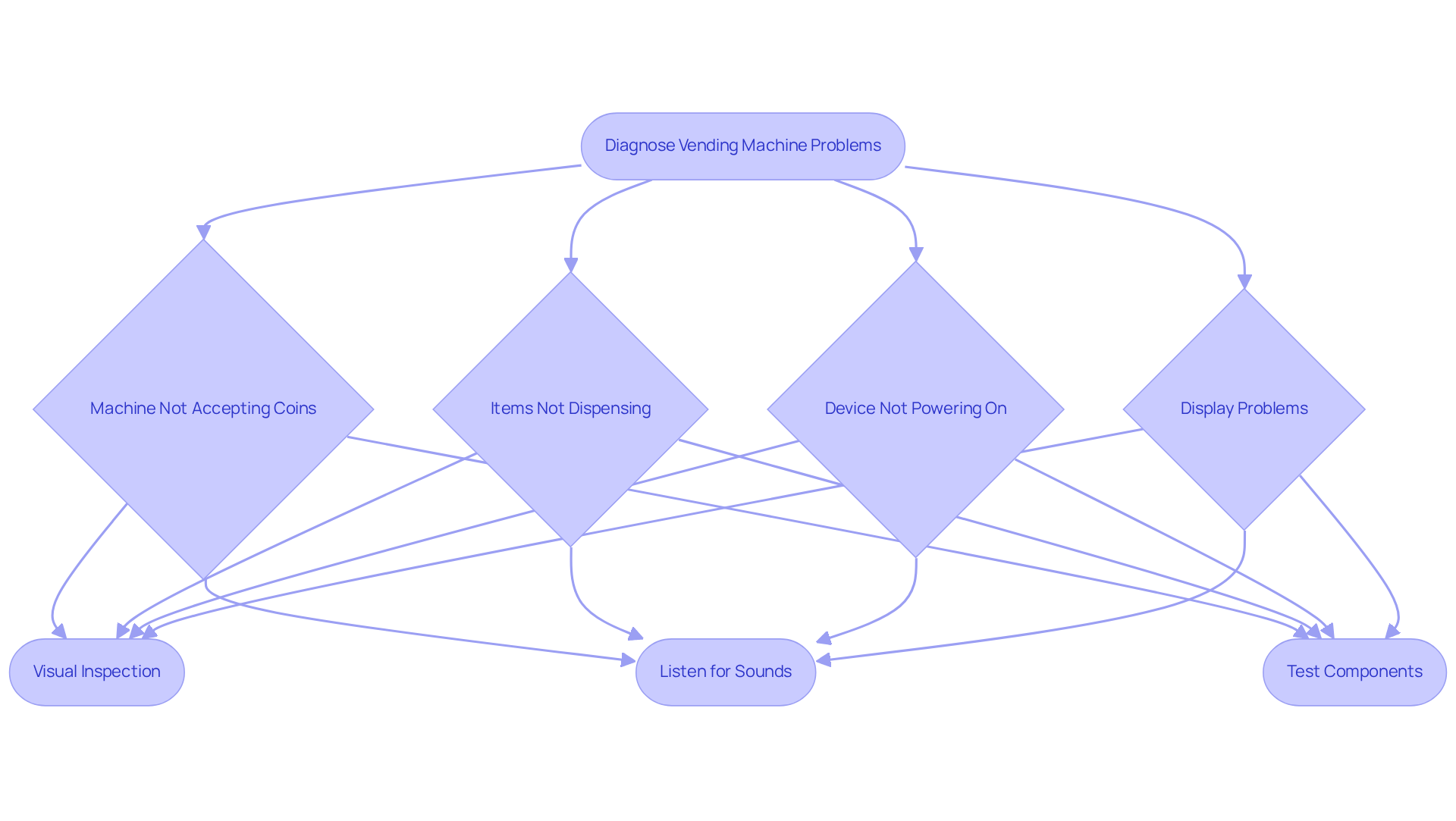

A vending machine fixer needs a straightforward approach to identify problems in vending devices. Let’s dive into some common issues and how you can spot them:

Machine Not Accepting Coins: First off, check for any jammed coins or a coin mechanism that might be acting up. Make sure the coin slot is clean and free of debris.

Items Not Dispensing: If products aren’t coming out, it could be a jammed item or a faulty motor. Take a look at the and ensure nothing is stuck.

Device Not Powering On: Is your machine not turning on? Confirm it’s plugged in and check the circuit breaker. A multimeter can help you test the power supply.

Display Problems: If the display isn’t working right, it might be a wiring issue or a defective display board. Inspect the connections and replace the board if needed.

Now, let’s break down some diagnostic steps:

- Visual Inspection: Start with a thorough visual check of the machine for any obvious issues.

- Listen for Sounds: Pay attention to any unusual sounds that could indicate mechanical problems.

- Test Components: Use your multimeter to test electrical components for continuity and functionality.

By following these steps, you can quickly resolve common vending problems like a vending machine fixer. It’s all about being methodical and staying on top of things!

Execute Repairs: Step-by-Step Instructions

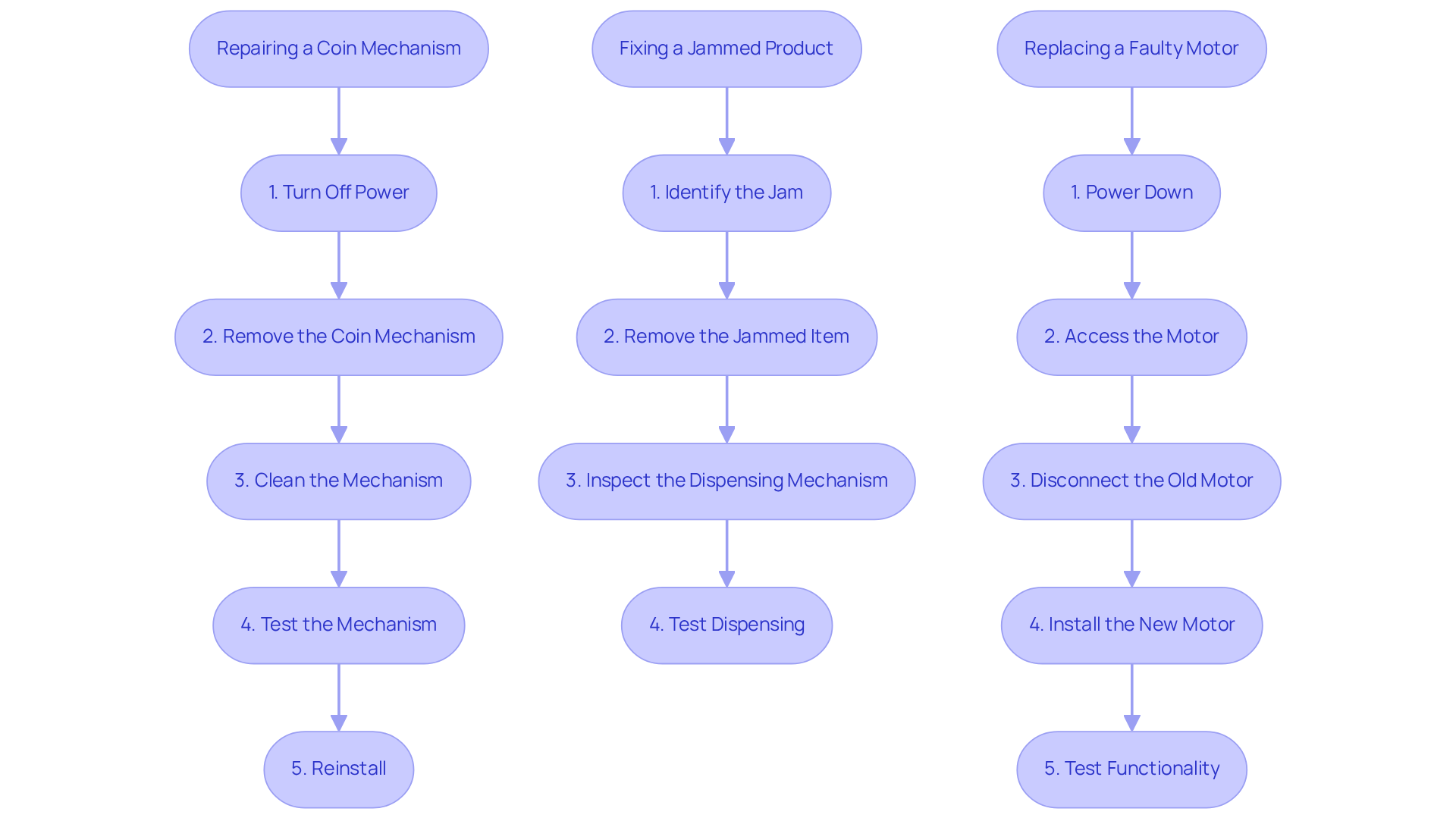

Once you’ve diagnosed the problem, let’s dive into some step-by-step instructions to get those repairs done right.

Repairing a Coin Mechanism:

- Turn Off Power: First things first, make sure the device is powered down. We want to avoid any electrical hazards, right?

- Remove the Coin Mechanism: Next, unscrew the mechanism from the device and carefully disconnect any wiring. Take your time here.

- Clean the Mechanism: Grab a soft brush and a suitable cleaning solution to wipe away any dirt or debris. This stuff can really mess with functionality.

- Test the Mechanism: Now, reconnect the mechanism and test it with some coins. You want to make sure it’s working properly and detecting coins accurately to avoid any counterfeit issues. By the way, that gumball device coin mechanism, priced at $55.99, has a clutch handle safety system to ensure proper coin usage.

- Reinstall: Once you’ve confirmed it’s working, securely reinstall the mechanism. This step is crucial for stability during operation. And don’t forget, it also has built-in vandalism protection, which is essential for safeguarding profits from the vending unit.

Fixing a Jammed Product:

- Identify the Jam: Open up the device and locate that jammed item that’s causing all the trouble.

- Remove the Jammed Item: Carefully extract the item without damaging the mechanism. We want to avoid further issues down the line.

- Inspect the Dispensing Mechanism: Check for any obstructions or damage that might affect future dispensing. A little inspection goes a long way.

- Test Dispensing: Run a quick test to ensure items are dispensing correctly. You want to confirm that the mechanism is fully operational.

Replacing a Faulty Motor:

- Power Down: Again, make sure the device is off to avoid any electrical risks during the repair.

- Access the Motor: Remove the necessary panels to get to the motor. You might need some specific tools for this.

- Disconnect the Old Motor: Unscrew and disconnect the wiring from the faulty motor. Take note of the connections for the new installation.

- Install the New Motor: Connect the new motor and secure it in place. Make sure all connections are tight and correct.

- Test Functionality: Power on the device and test the motor’s operation. You want to confirm it’s functioning as intended.

By following these detailed instructions, you can effectively tackle common dispenser issues. This will help ensure smooth operation and . Plus, using high-quality components, like those with precise coin detection systems, can really boost the reliability of your automated retail operations.

Implement Maintenance Practices and Troubleshooting Techniques

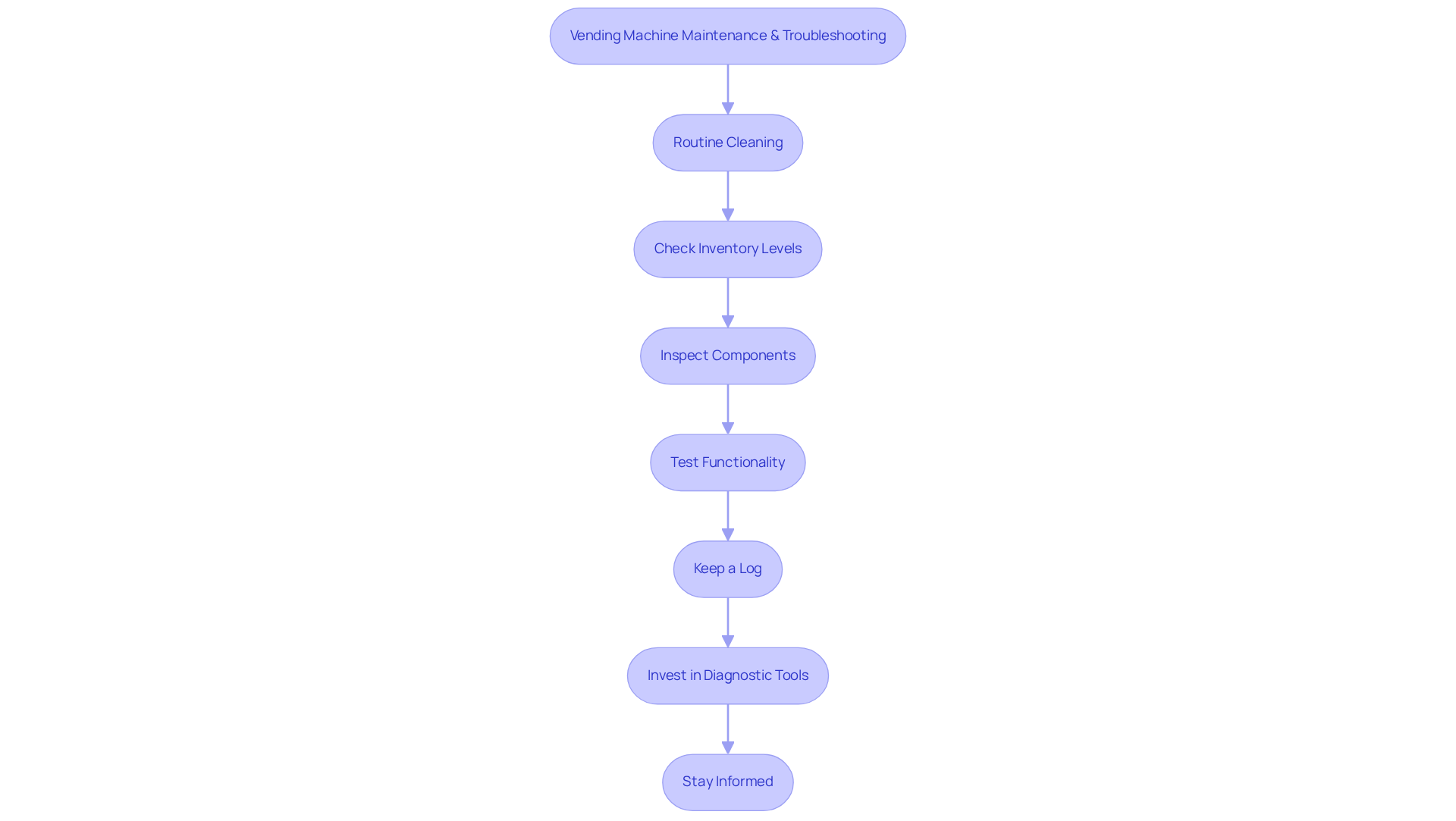

To keep your vending machines running smoothly and efficiently, let's dive into some practical maintenance practices and troubleshooting techniques that a can easily implement.

First up, routine cleaning. Give both the outside and inside of your machines a good clean regularly. This helps prevent that pesky buildup of dirt and grime that can cause issues down the line.

Next, it’s important to check inventory levels. Make it a habit to monitor product levels frequently. This way, you’ll ensure the machine is stocked and functioning as it should.

Don’t forget to inspect components. Take a moment to periodically check all the mechanical and electrical parts for any signs of wear and tear. It’s a small step that can save you a lot of trouble later.

And of course, you’ll want to test functionality. Regularly assess coin mechanisms, motors, and displays to catch any problems early on.

Now, let’s tackle some troubleshooting techniques. Start by keeping a log of repairs and maintenance activities. This can help you spot any recurring issues that might need a closer look.

Consider investing in diagnostic tools. These handy gadgets can help you pinpoint problems quickly, saving you time and hassle.

Lastly, make sure to stay informed. Keep up with the latest in automated retail technologies and repair techniques through online resources and forums. It’s all about staying ahead of the game.

By adopting these practices, you can really boost the performance and reliability of your vending machine fixer, ensuring they serve your customers effectively. So, why not start implementing these tips today?

Conclusion

To really shine as a vending machine fixer, it’s all about mastering the essential skills and tools for effective repairs and maintenance. This guide has laid out the key technical know-how, problem-solving skills, attention to detail, and customer service abilities you need to succeed in this field. Plus, having the right tools—like screwdrivers, multimeters, and cleaning supplies—makes sure you can tackle repairs efficiently.

Let’s talk about some key insights: diagnosing common vending machine problems, following step-by-step repair instructions, and implementing maintenance practices that boost the longevity and reliability of those machines. By addressing issues like coin acceptance failures, item dispensing hiccups, and electrical glitches through systematic troubleshooting, you can really cut down on downtime and keep customers happy. Regular maintenance and keeping accurate records are also crucial for a smooth operation.

Now, here’s the thing: becoming a skilled vending machine fixer isn’t just about having the technical skills and tools. It’s also about being committed to ongoing learning and adapting to new technologies in the automated retail space. Embracing these practices will not only enhance the service you provide to customers but also help you build a more successful and sustainable vending machine business.

So, if you’re ready to take the first steps toward mastering these skills, you’re on your way to a rewarding career in this essential service industry.

Frequently Asked Questions

What essential skills are needed for vending machine repair?

Essential skills for vending machine repair include technical knowledge of how vending machines work, problem-solving skills for troubleshooting issues, attention to detail for accurate diagnoses and repairs, and customer service skills for effective communication with clients.

What tools are necessary for a vending machine technician?

Necessary tools for a vending machine technician include a solid set of Phillips and flathead screwdrivers, a multimeter for testing electrical components, adjustable wrenches for tightening or loosening bolts, a stash of common replacement parts like belts and motors, and cleaning supplies for maintaining machine cleanliness.

What common problems should a vending machine technician be aware of?

A vending machine technician should be aware of common problems such as cooling failures, mechanical jams, and payment system failures, as recognizing these issues early can prevent larger problems later on.

Why is record keeping important in vending machine repair?

Record keeping is vital in vending machine repair for accountability and tracking performance, helping technicians make informed decisions about future maintenance and replacements.

How can attention to detail benefit a vending machine technician?

Attention to detail benefits a vending machine technician by ensuring thorough diagnostics and repairs, which helps machines run smoothly and effectively.

List of Sources

- Understand Essential Skills and Tools for Vending Machine Repair

- O*NET Code Connector - Coin, Vending, and Amusement Machine Servicers and Repairers - 49-9091.00 (https://onetcodeconnector.org/ccreport/49-9091.00)

- How to Fix a Pop Machine: Essential Steps for Property Managers (https://blog.vendingvillage.com/how-to-fix-a-pop-machine-essential-steps-for-property-managers)

- How To Refurbish Your Vending Machine - VSI Vending & Coffee Services (https://vsivendingservices.com/2023/05/how-to-refurbish-your-vending-machine)

- Execute Repairs: Step-by-Step Instructions

- Amazon.com: Coin Mechanism Vending Machine Coin Mech for Two Coins $0.50 Purchase - Gumball Machine Replacement Parts 25 Cent Coin Mechanism for Beaver & Candy Machine & Vending Machine by Entervending : Industrial & Scientific (https://amazon.com/Coin-Mechanism-Vending-Machine-Mech/dp/B0DKZN5VS4)